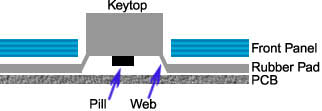

Anatomy of a Rubber Keypad

|

Most rubber keypads are custom

design to a specific customer drawing. While designing a

rubber keypad, there are a few things that can be done to help

reduce costs and improve performance. A few of the critical issues are:

|

|

The "pill" is pushed onto the PCB, and makes the electrical connection. The "web" design determines the amount of tactile feedback. See below. |

|

|

Web Design |

|||

|

|

||

|

|

||

|

|

||